ELT INOX

.jpg)

Stainless steel stacker truck with lifting function of the stabilisers to overcome obstacles

PERFORMANCE, SAFETY AND STABILITY, HYGIENE AND EASY CLEANING

ELT INOX stacker truck by Samag is made of stainless steel or non-corrosive material, thus intended to be used in environments where cleanliness and hygiene are essential conditions and where there are problems of corrosion.

All made with:

- stainless steel frame - including linkage under the forks - bushes and bearings

- frame with rounded shapes to reduce the deposit of residues and allow a good daily washing with fresh water

- lifting cylinder (including pulley lifting chain) fully made of stainless steel or non-corrosive material

- AISI 304 cast stainless steel gearbox casing

- bonnet and tiller arm with protection degree against water sprays

- brushless AC alternating current traction motor: less maintenance and more power

- stainless steel bearings, pins and bushes on wheels, rollers and masts

- spring loaded central drive wheel with adjustable load, for efficient ground contact at all times

- plastic push-button control box resistant to corrosive agents and protected

- Cold store version (upon request)

✔ LOAD CAPACITY UP TO 1.200 KG AND 1.500 KG

✔ SPECIAL CONSTRUCTIONS UPON REQUEST

✔ SPECIAL DIMENSIONS UPON REQUEST

- some optionals

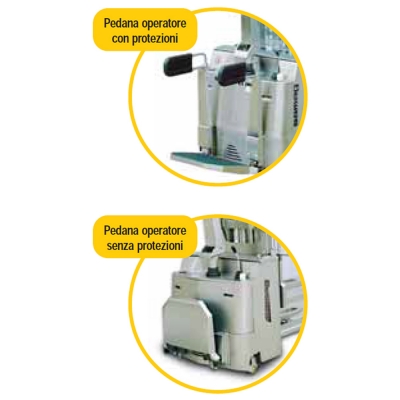

- Operator transport platform

- Lithium battery

- Scale/Printer

- Use in cold store

| Type | Stainless steel forklift trucks | Class | Stainless steel stackers with built-in pallet truck function for normal-intensive use |

|---|---|---|---|

| Load capacity (Kg) | 1500 | Lifting capacity (mm) | 3500 |

|

|

1.1 |

Manufacturer |

|

|

SAMAG |

|

|---|---|---|---|---|---|---|

|

Characteristics |

1.2 | Manufacturer's type designation | ELT INOX | ELT INOX P.O. | ||

| 1.3 | Drive: electric (battery or mains), diesel, petrol, fuel gas | Electric | ||||

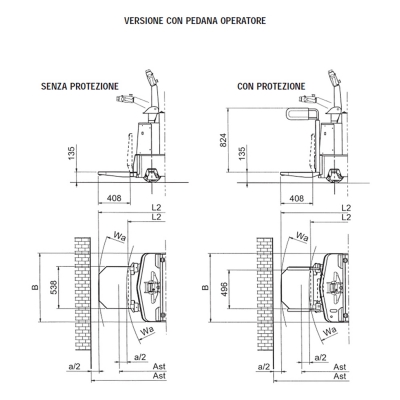

| 1.4 | Operator type: hand, pedestrian, standing, seated, order-picker | pedestrian | seated | |||

| 1.5 | Load capacity/rated load | Q | t | 1,2 (1) | ||

| 1.6 | Load centre distance | C | mm | 600 | ||

| 1.8 | Load distance, centre of drive axle to fork | x | mm | 713 (3) | ||

| 1.9 | Wheelbase | Y | mm | 1232 (2) | ||

|

Weight |

2.1 | Service weight (battery included) | Kg | 985 | 1070 | |

| 2.2 | Axle loading, laden (front / rear) | Kg | 840 / 1345 | 946 / 1324 | ||

| 2.3 | Axle loading, unladen (front / rear) | Kg | 725 / 260 | 830 / 240 | ||

|

Wheels and frame |

3.1 | Tyres: solid rubber, superelastic, pneumatic, polyurethane | Large band Topthane | |||

| 3.2 | Tyre size, front | mm | 260 x 85 / 125 x 50 | |||

| 3.3 | Tyre size, rear | mm | 85x70 | |||

| 3.5 | Wheels, number front rear (x = driven wheels) | 1X - 2/4 | ||||

| 3.6 | Tread, front | b10 | mm | 754 | ||

| 3.7 | Tread, rear | b11 | mm | 370 | ||

|

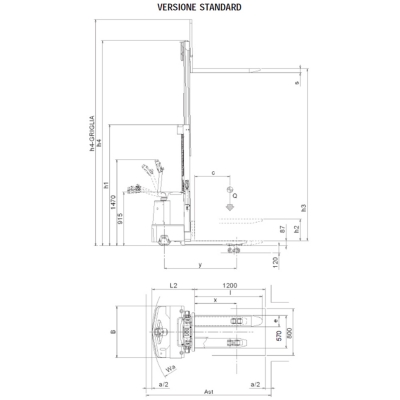

Dimensions |

4.2 | Height, mast lowered | h1 | mm | (see table) | |

| 4.3 | Free lift | h2 | mm | (see table) | ||

| 4.4 | Lift | h3 | mm | (see table) | ||

| 4.5 | Height, mast extended | h4 | mm | (see table) | ||

| 4.6 | Initial lift | h5 | mm | 120 | ||

| 4.8 | Seat height / stand height | h7 | mm | --- | 135 | |

| 4.9 | Height of tiller in drive position (min. / max.) | h14 | mm | 992 / 1366 | 1186 / 1386 | |

| 4.15 | Height of forks from ground | h13 | mm | 87 | ||

| 4.19 | Overall length | l1 | mm | 1874 | 1982 - 2356 (3) | |

| 4.20 | Lenght of face of forks | l2 | mm | 724 | 832 - 1206 (3) | |

| 4.21 | Overall width | b1 | mm | 880 | ||

| 4.22 | Fork dimensions | slell | mm | 60 x 200 x 1150 | ||

| 4.24 | Fork - carriage width | b3 | mm | 700 | ||

| 4.25 | External fork widths | b5 | mm | 570 | ||

| 4.32 | Ground clearance, centre of wheelbase | m2 | mm | 28 | ||

| 4.34 | Aisle width for pallets 800 x 1200 crossways | Ast | mm | 2124 | 2255 - 2613 (4) | |

| 4.35 | Turning radius | Wa | mm | 1437 (3) | 1579 - 1937 (3)(4) | |

|

Performance |

5.1 | Travel speed (laden / unladen) | Km/h | 6 / 6 | 6 / 6 - 7,5 / 7,5 | |

| 5.2 | Lift speed (laden / unladen) | m/s | 0,12 / 0,22 | |||

| 5.3 | Lowering speed (laden / unladen) | m/s | 0,30 / 0,24 | |||

| 5.7 | Gradeability (laden / unladen) | % | 7 / 9 | |||

| 5.8 | Max. gradeability (laden / unladen) | % | 7 / 15 | |||

| 5.10 | Service brake | Electric | ||||

|

Electric motor |

6.1 | Traction motor, power KB 60' | KW | 1,8 AC | ||

| 6.2 | Lifting motor, performance 15% ED | KW | 2,5 | |||

| 6.3 | Battery DIN 43531/35/36 A, B, C, | yes | ||||

| 6.4 | Tension / nominal capacity | V / Ah | 24/240 | |||

| 6.5 | Battery weight (± 5%) | Kg | 205 | |||

|

Altri dati |

8.1 | Control type | Electric AC | |||

| 8.4 | Sound level at the driver's ear according to DIN 10 053 | dB/(A) | <70 | |||

| Ast comprende "a" (spazio di manovra) = 200 mm ed è inteso per posto pallet vuoto (1) Come trasportatore + 20% (2) Con stabilizzatori sollevati aumenta di 120 mm (3) Con stabilizzatori sollevati diminuisce di 46 mm (4) Pedana verticale / Pedana orizzontale |

||||||

OVERALL DIMENSIONS OF LIFTING GROUPS |

||||||

|---|---|---|---|---|---|---|

|

|

Lift height | h3 | h2 | h1 | h4 | h4 grid |

|

|

||||||

|

Non telescopic NT |

1700 | 1620 | 1620 | 2110 | 2130 | 2550 |

|

|

||||||

|

Duplex "D" |

2500 | 2430 | 350 | 1810 | 2995 | 3350 |

| 3000 | 2930 | 350 | 2060 | 3490 | 3860 | |

| 3500 | 3430 | 350 | 2310 | 3995 | 4360 | |