EGO INOX NEW

Stainless steel stacker truck

PERFORMANCE, SAFETY AND STABILITY, HYGIENE AND EASY CLEANING

EGO INOX stacker truck by Samag is made of stainless steel or non-corrosive material, thus intended to be used in environments where cleanliness and hygiene are essential conditions and where there are problems of corrosion.

All made with:

- Truck frame with lower base and closed in the area of the new swivel castor wheels.

- Reinforced frame in the lower area (swivel castor side) and upper area (area of bonnet).

- Chassis with simpler design for better cleaning facility.

- Drive wheel protection cover area, wider for better access to the front wheels.

- Protected and watertight hour meter and check control instrument.

- Tiller arm support base with double gasket for a better sealing inside the bonnet area.

- Reinforced fixed lift masts in the upper area.

- Predisposition for making more accessible the fitting of hydraulic hoses.

- Forks made from bent sheet metal, without external gaps, for better cleaning and greater structural rigidity.

- New version of the free lift mast for better visibility and simple maintenance.

- Push-button control box with encased control buttons totally in stainless steel and new IP67 protected microswitch.

Some optionals

- Battery from 210 Ah

- Platform for operator transport without or without side protection gates.

- Lithium battery

- Inbuilt charger

- Special dimensions.

✔ LOAD CAPACITY UP TO 1.100 KG AND 1.200 KG

✔ SPECIAL CONSTRUCTIONS UPON REQUEST

✔ SPECIAL DIMENSIONS UPON REQUEST

- some optionals

- Operator transport platform

- 240 Ah Battery

- Lithium Battery

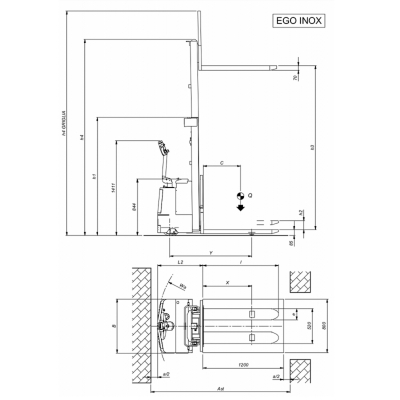

| Type | Stainless steel forklift trucks | Class | Stainless steel stackers for non-intensive use |

|---|---|---|---|

| Load capacity (Kg) | 1200 | Lifting capacity (mm) | 3500 |

| 1.1 | Manufacturer | SAMAG | SAMAG | |||

|---|---|---|---|---|---|---|

| Characteristics | 1.2 | Manufacturer's type designation | EGO INOX | EGO INOX | ||

| 1.3 | Drive: electric (battery or mains), diesel, petrol, fuel gas | Electric | Electric | |||

| 1.4 | Operator type: hand, pedestrian, standing, seated, order-picker | pedestrian | pedestrian | |||

| 1.5 | Load capacity/rated load | Q | t | 1,1 | 1,2* | |

| 1.6 | Load centre distance | C | mm | 600 | 600 | |

| 1.8 | Load distance, centre of drive axle to fork | x | mm | 720 | 720 | |

| 1.9 | Wheelbase | Y | mm | 1222 | 1297 | |

| Weight | 2.1 | Service weight (battery included) | Kg | 805 | 930 | |

| 2.2 | Axle loading, laden (front / rear) | Kg | 713 / 1192 | 811 / 1319 | ||

| 2.3 | Axle loading, unladen (front / rear) | Kg | 605 / 200 | 700 / 230 | ||

| Wheels and frame | 3.1 | Tyres: solid rubber, superelastic, pneumatic, polyurethane | Topthane wide strip | Topthane wide strip | ||

| 3.2 | Tyre size, front | mm | 240x70 / 100x60 | 240x70 / 100x60 | ||

| 3.3 | Tyre size, rear | mm | 85x70 | 85x70 | ||

| 3.5 | Wheels, number front rear (x = driven wheels) | 1x + 2/4 | 1x + 2/4 | |||

| 3.6 | Tread, front | b10 | mm | 625 | 625 | |

| 3.7 | Tread, rear | b11 | mm | 350 | 350 | |

| Dimensions | 4.2 | Height, mast lowered | h1 | mm | (see table) | (see table) |

| 4.3 | Free lift | h2 | mm | (see table) | (see table) | |

| 4.4 | Lift | h3 | mm | (see table) | (see table) | |

| 4.5 | Height, mast extended | h4 | mm | (see table) | (see table) | |

| 4.9 | Height of tiller in drive position (min. / max.) | h14 | mm | 860 / 1913 | 860 / 1913 | |

| 4.15 | Height of forks from ground | h13 | mm | 85 | 85 | |

| 4.19 | Overall length | l1 | mm | 1805 | 1890 | |

| 4.20 | Lenght of face of forks | l2 | mm | 685 | 765 | |

| 4.21 | Overall width | b1 | mm | 800 | 800 | |

| 4.22 | Fork dimensions | slell | mm | 70 x 170 x 1150 | 70 x 170 x 1150 | |

| 4.24 | Fork - carriage width | b3 | mm | 610 | 610 | |

| 4.25 | External fork widths | b5 | mm | 520 | 520 | |

| 4.32 | Ground clearance, centre of wheelbase | m2 | mm | 40 | 40 | |

| 4.34 | Aisle width for pallets 800 x 1200 crossways | Ast | mm | 2086 | 2166 | |

| 4.35 | Turning radius | Wa | mm | 1406 | 1480 | |

| Performance | 5.1 | Travel speed (laden / unladen) | Km/h | 6 / 6 | 6 / 6 | |

| 5.2 | Lift speed (laden / unladen) | m/s | 0,16 / 0,20 | 0,16 / 0,20 | ||

| 5.3 | Lowering speed (laden / unladen) | m/s | 0,23 / 0,18 | 0,23 / 0,18 | ||

| 5.7 | Gradeability (laden / unladen) | % | 7 / 9 | 7 / 9 | ||

| 5.8 | Max. gradeability (laden / unladen) | % | 7 / 15 | 7 / 15 | ||

| 5.10 | Service brake | Electric | Electric | |||

| Electric motor | 6.1 | Traction motor, power KB 60' | KW | 0,8 AC | 0,8 AC | |

| 6.2 | Lifting motor, performance 15% ED | KW | 2,2 | 2,2 | ||

| 6.3 | Battery DIN 43531/35/36 A, B, C, | yes | yes | |||

| 6.4 | Tension / nominal capacity | V / Ah | 24 / 160 | 24 / 240 | ||

| 6.5 | Battery weight (± 5%) | Kg | 150 | 150 | ||

| Other data | 8.1 | Control type | Electric AC | Electric AC | ||

| 8.4 | Sound level at the driver's ear according to DIN 10 053 | dB/(A) | <70 | <70 | ||

| Ast includes “a” (manoeuvring space) = 200 mm and means empty pallet space *Available with platform without side protections |

||||||

OVERALL DIMENSIONS OF LIFTING GROUPS |

|||||||

|---|---|---|---|---|---|---|---|

| Lift height | h3 | h2 | h1 | h4 | h4 grid | h5 | |

| Non telescopic NT | 1700 | 1620 | 1620 | 2080 | 2105 | 2510 | |

| Duplex "D" | 2500 | 2425 | 170 | 1750 | 2910 | 3315 | |

| 3000 | 2920 | 176 | 2000 | 3405 | 3810 | ||

| 3500 | 3420 | 196 | 2260 | 3905 | 4310 | ||

| Duplex "DVL" | 2500 | 2445 | / | 1780 | 2995 | 3335 | 1230 |

| 3000 | 2945 | / | 2030 | 3495 | 3835 | 1480 | |

| 3500 | 3445 | / | 2280 | 3995 | 4335 | 1730 | |